5 ways Sage Oil Vac preventive maintenance solutions can improve your bottom line

Many times, people don’t realize how much profitability is left on the table to extra labor costs, machine downtime and lost productivity if they don’t follow best practices for preventive maintenance. A worst-case scenario would be a crew standing around waiting for a machine that has suffered a catastrophic failure. While not every machine breakdown can be avoided, following regular preventive maintenance schedules greatly reduces the likelihood of significant machine failures.

Whether you have a construction or rental business or are on the dealership side, you’ll find that Sage Oil Vac mobile lube systems are designed to help you limit downtime and boost your bottom line.

Here are 5 key preventive maintenance advantages you get with Sage Oil Vac equipment.

1. Reduced transport costs and more timely preventive maintenance

Performing preventive equipment maintenance directly on the jobsite offers significant advantages. For starters, waiting for machines to return to the yard for maintenance can translate into missed or delayed service intervals, placing machine reliability at risk. Servicing equipment while it is in the field also yields time and transportation savings. The financial benefit really depends on your approach to mobile lube service and, ultimately, on which mobile lube system you use.

2. Better use of technicians’ time

Service and maintenance technicians are difficult to find, so you want to ensure the best use of their time. The pump-free Sage Oil Vac vacuum-operated system is much quicker than a traditional pump system, which means a technician can complete more oil changes per day — saving you money on labor.

Consider this real-life example. Michigan CAT documented their actual time savings while servicing a group of power generators in Michigan’s lower peninsula. This job required the removal and replacement of 110 gallons of oil for each machine. Using a conventional, pump-driven system — typically delivering two 55-gallon barrels of oil to the jobsite, switching out oil manually, and returning used oil barrels to a central shop — Michigan CAT service technicians averaged almost three hours per oil change. Each generator oil change took about three hours. After switching to a Sage Oil Vac 1C5F-2100 preventive maintenance trailer, this time was slashed to 69 minutes!

3. Less time maintaining lube equipment

Most mobile lube equipment manufacturers use mechanical pumps to transfer fluids, which require regular maintenance and repair. And, since each tank on a mobile lube system has a diaphragm and a mechanical pump, maintenance and repair needs for these systems can be time-consuming and costly, especially when you consider equipment downtime. The Sage Oil Vac system uses compressed air to push oil out of the tank — no pump required. To empty used oil out of tanks, you simply reverse the process to create a vacuum within the tank.

The time it takes to maintain your mobile lube system takes away from the time you spend performing preventive maintenance on your production machinery. Every minute your equipment is down for service, it costs you money. The Sage Oil Vac system is designed to get you up and running more quickly. This allows you to maximize equipment utilization rates and increase the return on your investment.

4. Lowered system operating expenses

Some mobile lube systems are more costly to operate due to their design. For instance, conventional diaphragm pumps and air piston pumps require a constant volume of air for the air compressor. Running an air compressor to operate a mobile lube system consumes fuel and increases maintenance costs. The Sage Oil Vac system reduces air compressor run time by up to 70% over a conventional system. We recommend shutting off the compressor when the used oil tank has a full vacuum and the fresh oil system is pressured to 80 psi. This reduces wear and tear, noise and fuel consumption.

5. Stays clean

Sage Oil Vac’s enclosed systems prevent contamination, which is the enemy of any tight tolerance and is costly to replace failed components. For instance, hydraulic systems continue to use tighter tolerances for higher performance, which demands close attention to oil cleanliness and best handling practices. Any significant contamination will significantly reduce equipment life.

And, since Sage Oil Vac systems use patented vacuum technology and have no moving parts inside the tanks, they are completely sealed. There is no opportunity for contamination to enter the lubricant tanks. On the contrary, mechanical pump systems require air-breathers to vent tanks, which can lead to contamination over time.

Choose the right solution for your business

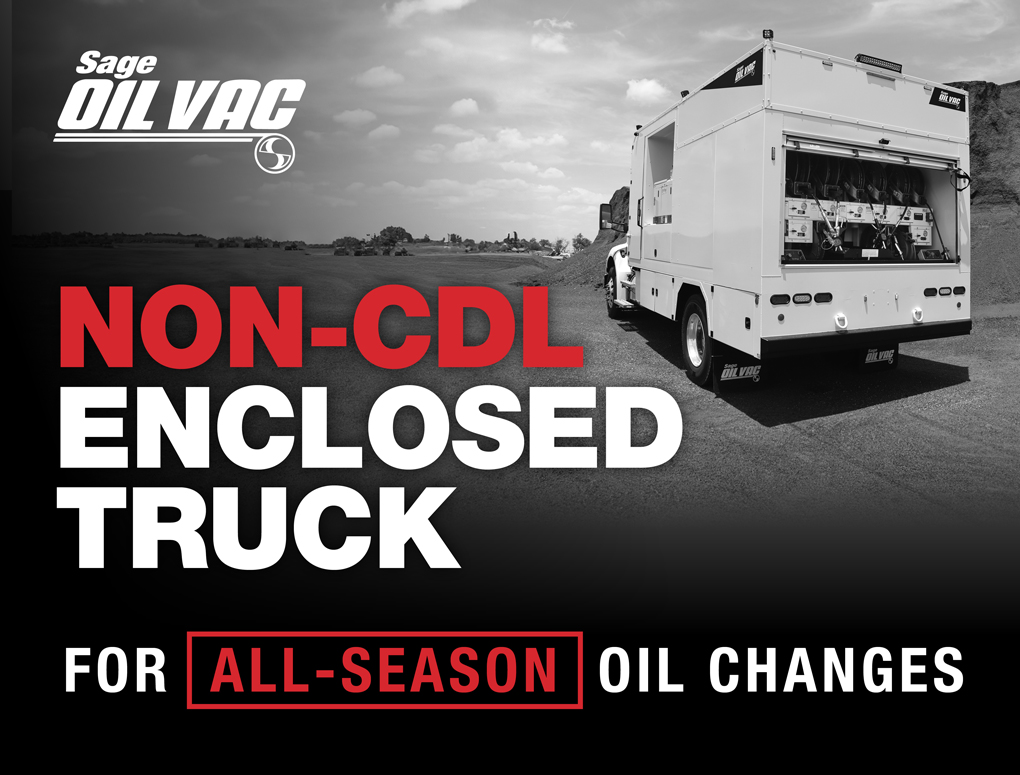

Sage Oil Vac offers a wide range of solutions to ensure you get the right lube system to match your needs. To find your most efficient solution, consider mobility, system/tank sizes, CDL requirements, pump type and accessories needed to make the job go smoothly. Mobile lube systems come in a variety of shapes and sizes. Sage Oil Vac options range from lube carts, skid trailers and lube bodies to our fully customized LubeBuilder™ system, and from tanks to reels and everything in between.

Finding the best solution for your needs helps drive efficiency. For instance, a large lube truck may allow you to service more equipment before returning to the shop, but a non-CDL truck under 26,000 pounds will broaden your pool of service technicians since it doesn’t require a CDL to operate.

A mobile lube system can be beneficial to your overall success. They can help you improve productivity and work more efficiently. But not all mobile lube systems are created equal. The pump-free Sage Oil Vac system is designed to maximize your bottom line. View the complete line of Sage Oil Vac mobile lube solutions, and talk to your dealer to see which system is right for you.