On the jobsite, a piece of machinery is only making you money when it’s running. Downtime — whether from unexpected breakdowns or routine maintenance — is a quick culprit of productivity and revenue loss. At the end of the day, anything you can do to keep the wheels turning and engines running will contribute to an operation’s bottom line.

Sage mobile lube systems can make a universal task quicker and more efficient, helping every machine spend more time doing its job. Like any piece of equipment on a worksite, a Sage system is designed to take care of a very specific function: Conduct lubrication and oil changes in the field. That makes it important to purchase and operate the right system to meet your specific mobile lubrication and maintenance needs with minimal work disruption, helping sustain and improve the return on investment (ROI) of machinery and equipment.

“Whether you’re moving beyond using buckets to manually change oil, driving machinery back to a shop to conduct maintenance or you’re upgrading from a different type of mobile lubrication system, a Sage system can help you keep your machinery operating by efficiently taking care of these common maintenance tasks in the field,” said Sage CEO Aaron Sage. “To maximize that efficiency, you have to match your Sage system to your specific jobsite maintenance needs.”

Here are a few things to consider in determining which Sage system is right for your operation.

Your biggest fluid management pain points: This may be the mess of manual oil changes, the time required to conduct maintenance with current methods or having the right workforce to do the job efficiently.

What you’re using to change oil now: Are you changing oil manually with buckets, or using another type of lubrication maintenance system?

Where you’re conducting maintenance: Are you changing oil and servicing machinery in a central shop or doing it on the job site?

How much machinery you’re maintaining: How many machines and different types are you maintaining?

Service frequency: How often do you change oil in the machines you service?

Maintenance services you’re providing: Are you simply topping off fluids on-site and seldom conduct full oil changes, transmission and full hydraulic exchanges, as well as 250 hour engine oil changes?

Current equipment: Do you already have trucks, skids or trailers? What is your existing payload or towing capacity?

Time on the road: How far do you travel between jobsites? How far do you travel before you make it back to the shop?

How you handle waste fluids: Do you dispose of used engine oil and other fluids in a central location? How frequently do you dispose of waste fluids?

Working conditions: Do you change oil and provide maintenance in cold temperatures that would require heated fluid tanks? Do you work best in an open or enclosed system?

Working with used oil filters: Consider ways to avoid the messiest part of the job with a Filter Stinger and used filter receptacle

Other tools and equipment: Do you have your own compressor? Do you need storage for supplemental jobsite tools and equipment?

Answering these questions about your specific operation is especially important, given the range of Sage mobile lube equipment options ranging from lube carts and skids to the largest trailers and Class 8 trucks that can provide service to multiple pieces of machinery on different jobsites. Once you know the specific improvements you want to make to your jobsite maintenance operations, it can help you know what system will work best for your business, in both the short and long term.

“Being able to identify these parts of your operation is important to your ability to select the right Sage system that can both meet your needs as well as fit in with existing equipment and processes,” Sage said. “Starting the process of integrating a Sage system — whether a lube truck, skid or trailer — into your business by having a clear picture of where you stand today can help you identify the direction to go in the future to achieve gains in productivity and efficiency that can help your business grow. We think of Sage systems as not just tools to do a job, but components of a strong growth strategy.”

Start the process to evolving your mobile lubrication services by checking out the range of Sage system options.

Growing pains always accompany periods of major business expansion. The right innovation can help streamline that growth, and for Dickinson Fleet Services that turned out to be a partnership with Sage Oil Vac.

One of the growing pains Dickinson faced was delivering oil to a large customer’s fleet. Not only would Dickinson need a much larger fleet of service trucks, but also a new level of efficiency to ensure the company continued to meet its customers’ growing needs. A decade ago, the Indianapolis, Indiana-based company had around 50 service trucks operating from nine retail locations in the Midwest and Eastern U.S.

Though the company was already poised to grow to meet its customers’ evolving needs, Dickinson’s growth and efficiency gains have come more quickly and easily in the last five years in part because of its partnership with Sage. Today, Dickinson has service technicians at locations in 38 states providing mobile truck maintenance and service, including preventative maintenance, accident damage repair and Department of Transportation inspections and certifications, with its own fleet of more than 450 service trucks. Each of those trucks uses a Sage Oil Vac system.

“Shortly after I came on board, I heard about the Sage systems and we realized they represented a safer, cleaner and overall better operating system than what we had been using in our trucks,” said Dickinson Fleet Services Vice President for Purchasing and Asset Management Don Gregory. “Sage Oil Vac systems have been a huge help in our expansion in how easily they fit into our trucks and how efficiently they enable us to operate.”

Building efficiencies with Sage

Previously, Gregory said Dickinson mobile service trucks used a pump-style system for oil change operations, and there was always lingering apprehension about pumps and tanks leaking, resulting in inefficiencies that could slow down daily operations and impede future expansion. “With Sage, I don’t worry about that at all. I feel very confident with this equipment. We don’t have issues with failing pumps and oil leaks like we did before,” he said.

Growth was already a target for Dickinson Fleet Services leadership when the company partnered with Sage Oil Vac two years ago. For Gregory, the decision to work with Sage as Dickinson’s growth continued made sense because of shared emphases on service and efficiency. Upon learning of the new efficiencies Sage systems could create for Dickinson mobile service trucks, for example, Gregory said the normal caution with which his company typically approaches new innovations quickly faded.

“We looked into Sage systems cautiously, as we do with any change. That caution went away pretty quickly with Sage. It wasn’t long after we tried their systems that we decided to integrate them into our whole fleet,” Gregory said. “They have great people, offer a great product and provide strong follow-up after the sale. They are proud of their product, you can see that pride in all of their people, and that inspires confidence in us as a partner.”

Though it’s difficult to quantify return on investment (ROI) improvements of Sage systems in Dickinson’s 450-truck mobile maintenance fleet, Gregory knows they have contributed to the company’s bottom line, both in terms of maintenance and efficiency of mobile service operations. The systems have been relatively low-maintenance since integrating them into the Dickinson fleet, and thus far Gregory has found them to be durable and long-lasting, two fundamental qualities he looks for in every new innovation to improve the company’s service vehicles.

“We are always improving our mobile trucks. We look at the overall ROI of the application of our fleet, and there has been an improvement,” he said. “We are always looking down the road because we want our equipment to last awhile, and we know that Sage systems will.”

Future growth plans

In the near future, Gregory said Dickinson will continue to improve its mobile service trucks as the company puts growing emphasis on overall fleet maintenance, not just truck maintenance, for its customers. For example, in addition to keeping up with new Sage system innovations, the Dickinson fleet is transitioning to aluminum body components. The goal: Make each service truck last a decade in the field.

“We’ve gone to an aluminum body that maintenance equipment resides inside of. We are setting a goal that every component within the box of that truck and chassis should last 10 years. We want all of our equipment to last that long. I am confident our Sage systems will last quite a while,” Gregory said. “Sage will always play a major role as we continue to refine and evolve these trucks in looking at different applications. We’re always going with Sage. I think switching to them has been one of the most strategic and smartest moves we’ve ever made.”

It’s always a good time to make sure your equipment is in top operating condition. Picture this: You’re just starting the day with a full schedule ahead and you get hit with a maintenance set back. Now, the whole day is thrown off — you might even have to reschedule a few things on the list. Whether it’s just bad luck or something you could have prevented, regular and thorough care of your equipment is the best bet for a smooth day on the job, no matter the season. Sage Oil Vac is always here to help, so we’ve compiled a list of preventative maintenance tips, tricks and advice:

In planning ahead for that busy time, it’s important to account for the machinery you’ll be maintaining and what it will need, according to Sage Oil Vac CEO Aaron Sage. “Make sure everything is serviced, including specific components like wheel bearings,” Sage said. “Ideally, you want to start the busy maintenance season with all of your machinery ready to run efficiently and without interruption.”

Don’t forget these components.

In addition to checking major mechanical and structural components, Sage said it’s important to inspect parts that many operators don’t typically think about when conducting early-season maintenance, including their Sage Oil Vac systems. “It starts with really basic maintenance, like ensuring your trailers are inspected and ready for the road,” Sage said. “The long game here is that you need to be efficient on the maintenance side.”

Equipment maintenance tips 101

Air Compressors: Your Sage Oil Vac is built to be dependable and long-lasting — this is in-part due to its very few moving parts. So, the air compressor is the most important part to keep maintained on your unit. Use the recommended maintenance schedules that come with the system for the engine and the compressor pump. An oil change on the engine and pump should be performed at least one time per year regardless of use on your system. Intake air filters should also be replaced at least one time per year.

Compressor air tanks should be drained daily during use. The Sage Oil Vac design (on some models) can result in a collection of used oil in the holding tanks that can accumulate from oil mist vacuumed into the holding tanks. This is harmless to the design of the system however, the used oil should be drained and disposed of properly to properly maintain the compressor.

Pro Tip: Operating your Sage Oil Vac continuously with the used oil tank completely full could result in a large amount of used oil accumulating within the compressor heads and air tanks. It’s important to unload the used oil tank if its capacity reaches 95 percent or before.

Ball Valves: Ball valve actuation can become loose over time and may need to be replaced. Check that that ball valve actuation on each ball valve is not so loose that they can open or close during routine travel to the jobsite.

Cam Locks: Cam lock fittings should have caps and plugs installed to reduce drips and spills. Female cam connections need to have both actuating arms intact and working to secure a good connection.

Filters: Sage units come with 10- to 25-micron fresh fluid filters for all new fluids. We recommend that these are changed two times per year or every 1,000 gallons of oil filtered.

Hose reels: Check the spring latch assembly of the hose reel to ensure that the reel is performing properly. Grease swivels should be greased at least once a year and more often for heavy use depending on the model. Double check that all ball stops are installed and tight to keep the hose reel tension in good shape.

Hoses: Sage Oil Vac uses 1,000+ psi hoses for their systems. Check the outer hose covers and look for any gouges or wear — this is especially important on spring retractable hose reels. Keep a lookout for spots where oil is seeping through the outer cover, as this could indicate that the inner lining of the hose has a rip or tear.

Hydraulic Connections: Clean off any grime or dirt from the hydraulic fittings for a secure connection to meters and equipment — any leaks should be addressed promptly.

Lug Nuts: The lug nuts on trailer wheels need to be tightened to the proper torque — this is an important responsibility that trailer owners and users need to be familiar with. Inadequate and/or inappropriate wheel nut torque (tightness) is a major reason that lug nuts loosen in service. Loose lug nuts can rapidly lead to a wheel separation and serious safety consequences.

Lug nuts are prone to loosen right after a wheel is mounted to a hub. When driving on a new or remounted wheel, check the lug nut tightness frequently during the first few hundred miles of the trailer’s use. A good rule of thumb is to check after the first 10, 25 and 50 miles of driving, before each tow, and at least twice per year thereafter.

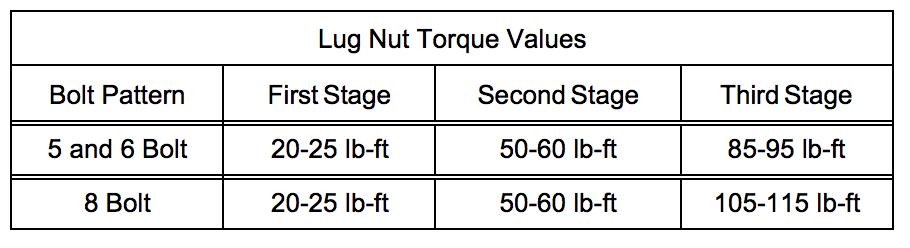

It’s also important that you tighten lug nuts to the proper torque for the axle size on your trailer to prevent wheels from coming loose. The only way to be certain you have tightened the lug nuts properly is with a torque wrench. Four-way wrenches, ratchets and similar tools can be useful for short-term emergency repairs but they’re not appropriate tools for adequately tightening lug nuts.

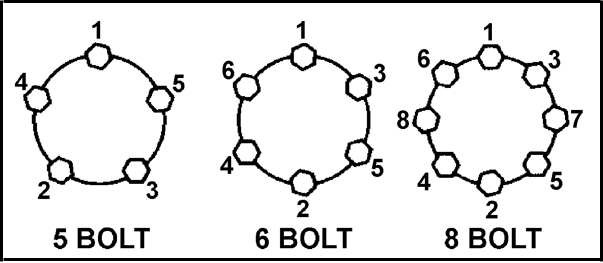

While tightness is important, be warned that overtightening can result in breaking the studs or permanently deforming the mounting stud holes in the wheels. Tighten per sequence in Figure 1 below. Using this sequence, tighten all lug nuts in three stages and to the torque values listed in Figure 2 for each stage.

Pro Tip: Keep a record of the date and approximate mileage of your last torque check somewhere on or inside your equipment. Make note of any lug nut that is loose and investigate the reason(s). If the lug nut tightness is not maintained after more than one re-tightening application, this indicates there is something wrong with the lug nuts, studs, wheels and/or hubs and must be corrected.

Figure 1. Lug Tightening Sequence

Figure 2. Lug Torque Requirements

Meters: Electronic meters will occasionally need new batteries. High flow non-drip ends should be cleaned regularly to for a proper close to keep drips and spills to a minimum.

Running Lights: Make sure all brake lights, turn signals, license plate lights and market lights work correctly.

Tires: Check the condition of the tire tread, and make sure there is adequate air pressure. Also inspect for gouges or other defects.

Sage Oil Vac Tanks: The Sage Oil Vac design ensures that very little outside dirt and elements are introduced into the tanks, protecting their cleanliness, but an annual flushing of the used oil tank is recommended to flush out sludge and other contaminants that have been vacuumed out of engines and drain pans with debris. To do this, vacuum 5-10 gallons of diesel, pressurize the tank (no more than 5 psi) and dispense the fluid to flush the tank and hose circuit. This same method can be used to switch fluids in new oil tanks if necessary — i.e., switching a 15W-40 motor oil tank to a hydraulic fluid tank.

Wheel Bearings: It’s recommended to grease wheel bearings every 12 months or 12,000 miles, whichever comes first. You can use red grease for trailer wheel bearings or wheel bearing grease, which is specially designed for use on trailer running gear. Wheel bearing grease has a slightly higher temperature rating, 520 degrees, compared to 510 degrees for the red grease.

When adding grease, make sure that the new is compatible with the old or remove the old grease completely. Incompatible greases can break each other down. Also, inspect the bearings and races before repacking them and replace the grease seals since they will likely be damaged in the process.

Consider equipment accessories for increased efficiency.

After you’ve inspected your equipment and ensured it’s ready for the jobsite, it’s a good time to consider any changes or additions you can make to become more efficient. That may mean adding new machinery or making smaller changes. For example, Sage said adding new drain plugs and hose assemblies can make oil changes cleaner and more efficient, especially when used alongside a Sage Oil Vac system.

“Once your machinery is ready to go, it’s a good time to start looking at a system to enable you to connect directly to machines for changing oil, making it cleaner and more efficient,” Sage said. “Cleaner drain plugs like those from Femco® work well with Sage Oil Vac systems and can make you better at your job of changing oil on the jobsite.”

Plan your maintenance operations.

Early in the busy season is a good time to look at ways you can streamline not just your equipment, but how you use it. Extended oil changes have been a growing trend in the automotive industry for some time now, and it’s starting to work its way into the construction sector. While it may work for some equipment, waiting longer between oil changes isn’t feasible for all machinery, largely because of working conditions. Prioritizing oil change jobs based on frequency and need is one way to make your operations more efficient.

“The deciding factor on that is the work environment. Is it a dirty environment? How hard is the machinery working? If it’s dirty and the machinery’s working hard, you can’t really delay oil changes,” Sage said. “If it’s an over-the-road truck that’s getting a lot of hours on it, but in cleaner working conditions at the same RPM for long periods, extended oil changes will work. If it’s an excavator ramping RPM up and down, working out in dirt storms and getting worked really hard, you need to monitor oil a lot more closely and keep oil changes more frequent.”

Regular maintenance is essential to keep equipment, accessories and your work environment safe and reliable. Do not hesitate to contact your Sage Oil Vac Dealer for any maintenance and equipment questions.

Our Sage Oil Vac dealer network is what makes us who we are today, and we wouldn’t be playing such a major role in our customers’ success if not for the men and women who sell and service Sage Oil Vac systems and equipment around the U.S. That’s why it’s important to us to give much-deserved “shout-outs” to the dealers who go beyond the call of duty in the criteria that make for a successful dealership, including participation in dealer marketing programs, product knowledge, promotional activity and year-over-year sales growth.

Platinum Award — Perfection Truck Equipment

Perfection Truck Equipment has come a long way in the over 70 years since starting out with nine employees and five truck lines. Today, the Oklahoma City, Oklahoma-based company supports more than 120 lines of trucks and 100 lines of truck and trailer mounted equipment primarily for the oil/gas and construction industries. The team at Perfection Truck Equipment has more than a century of combined experience in sales and service for the trucking industry, and a key component of that success recently has been the addition of Sage Oil Vac LubeBuilder and Lube Truck sales and service. They’ve been a valuable partner in a major geography for Sage Oil Vac, getting the Sage name in front of new customers while providing industry-leading service for existing ones.

Gold Award — ACME Truck Body

Construction and generator maintenance are the primary markets for ACME Truck Body in Vero Beach, Florida. Sage Oil Vac Lube Trucks and LubeBuilder systems are important in enabling ACME ‘s customers to do their jobs. And, Mark Steinberg at ACME Truck Body has become one of the leading sales and service providers for Sage systems since becoming part of our dealer network. They are true “go-getters” with sales and service who have helped expand the Sage customer base in the Florida construction industry marketplace.

Silver Award — Oil Patch Power

Dwayne Green has been working in the oil field business for a long time and has a lot of expertise. So, when he wanted to take his company, Midland, Texas-based Oil Patch Power to the next level five years ago, he became a Sage Oil Vac partner. Today, he’s among the nation’s leaders in Sage lube skids and lube system sales and service around the Permian Basin oil field across parts of Texas, Oklahoma and New Mexico. In addition to being one of the top Sage dealers in the country, Green has helped refine the Sage product line and leverages his co-op funds for advertising and trade shows around the Permian Basin region.

Outstanding New Dealer Award — Utility Equipment Service

When the folks at Utility Equipment Service in Spring Hill, Tennessee, were looking for a new product line to offer their customers in the construction and generator maintenance industries, they found Sage lube skids and trailers to be the perfect fit with their existing products and services. The team at Utility Equipment Service provides a wide array of construction equipment, work trucks and accessories, and are constantly working hard to evolve so they continue to surpass their customers’ expectations with the most up-to-date equipment sales and service. Their work ethic and ability to showcase Sage equipment are just a couple of reasons why they’re our Outstanding New Dealer for 2018.

Thank you to the entire team of Sage Oil Vac dealers, congratulations on another great year, and here’s to continued success in the future!

Service after the sale is a top priority for most contractors when investing in a piece of construction equipment, and can be what separates a quality equipment dealer from its competition. How quickly a service technician has a machine up and running after a breakdown or after doing routine preventative maintenance work is how most contractors gauge equipment dealers. So, to score high marks with customers, dealerships need to hire knowledgeable service technicians and equip them with everything they need to be efficient in the field.

Ditch Witch Sales of Michigan understands that its customers depend on them. With locations in Grandville and Howell, the two service techs for the dealership spend almost 100 percent of their time in the field performing routine maintenance and handling emergency service calls when the need arises. Homer Gonzalez, from the Grandville Ditch Witch Sales of Michigan location, is one of the technicians. His job has him traveling all over the state and working on a wide range of equipment.

“I was a service tech in the oil fields before going to work for the dealership, Gonzalez explained. “I enjoy the work. I get to visit a lot of jobsites and work on a lot of different machines. And while a large chunk of the work is doing routine maintenance things like oil changes, there are times where a machine goes down and I need to work as quickly as possible to get it working so customers can stay on schedule. It’s those times, where the parts and tools I have on my truck make a difference.”

Officing from the truck

Just like anyone in the construction industry, Gonzalez’s Ford 550-truck is his office, and he is incredibly strategic about how he uses every square inch. Its service box is outfitted with a service crane, welder and air compressor. The side compartments house tools, supplies and parts.

“I believe keeping everything organized, clean, and tidy is one of the keys to being a good field service technician,” Gonzalez said. “However, until recently keeping the bed of my truck that way was a real challenge because I was devoting so much space to hauling around buckets of fresh and used oil. A person can do their best to make sure they wipe up drips on the buckets before putting them back in, but as they bounce around on a rough road and shift while turning, you’re bound to have some leakage.”

Transporting buckets wasn’t the only issue that the Ditch Witch Sales of Michigan service technician ran into while performing routine oil changes. He also said that having buckets sitting around a machine and wiping oil drips up was creating an unprofessional image. He knew there had to be a better, more efficient, way of handling these fluids.

Discovering a more efficient mobile lube solution

Gonzalez’s quest to come up with a better mobile lubrication solution, and perhaps the desire to go home at night with clean hands, lead him to Hoekstra Truck Equipment, a Sage Oil Vac dealer in Grand Rapids, Michigan to see what the company’s options were for adding a mobile lube system to their service fleet.

“While working in the oil field, there were a lot of companies that used large mobile lube service trucks or trailers, but I wasn’t sure if anyone offered a system that could be fitted to an existing truck without taking up the entire bed,” Gonzalez explained. “Mike Thorsen with Hoekstra showed me a Sage Oil Vac mobile lube system and explained how their compressed air fluid exchange systems use vacuum technology to dispense fresh fluids and suction up waste fluids using an air compressor. He also told me that I could create my own customized system based on my needs and the space I had available in my truck. It sounded like a great solution to my problem.”

After consulting with Thorsen and the team at Sage Oil Vac, the Ditch Witch service technician decided to order a Sage LubeBuilder system with two 30 gallon tanks. He planned to dispense fresh oil from one of the tanks and dispose of waste oil in the other.

Installing the system

Sage Oil Vac designed its LubeBuilder System to be easy to install and highly customizable. Gonzalez received tanks, hoses, reels, control panels and all of the accessories needed to perform the install himself. “Sage Oil Vac provided easy to understand instructions and diagrams for installing the system in the back of my truck. The whole process took about 8 hours and was pretty easy. I probably could have wrapped it up faster, but I’m pretty particular about my truck so I took a bit longer,” he added.

Gonzalez mounted the two storage tanks toward the front of the truck bed, mounted the controls to a panel near a compartment near the cab and the two reels are mounted on the top of the gearbox. The truck’s existing air compressor powers the whole system. Between the two tanks, the service tech has created a small area to hold used filters and accessories.

Efficient operations

Since making the switch to a custom mobile lube system by Sage Oil Vac, Gonzalez estimates he’s been able to reduce the time it takes to service customer equipment by as much as 40 percent. Not carrying around buckets and drip pains has also freed up a significant amount of his truck bed, and replenishing his supply of fresh fluids and disposing of waste oil is also much easier.

“On the job, there’s no longer any wasted time wiping down buckets,” Gonzalez said. “Also, there is little chance of contaminants getting into the fresh oil because I’m using a closed system when I’m adding oil to my onboard tank and when I’m on the jobsite replenishing a machine’s fluids. The chance of spilling any oil on a jobsite is also greatly reduced. There isn’t any downside to using a system like this — only positives.”

With all of the efficiencies created by adding a custom mobile lube system to its Grandville service truck, Ditch Witch Sales of Michigan went ahead and ordered another LubeBuilder system for the service truck at its Howell location. Gonzalez said that he was able to help with the install and it was ready to go in less than six hours this time.

“Equipping our trucks with a mobile lube system frees up a lot of time during our week, which means we can be more responsive to our customers’ needs. And, the system we chose is perfect because it’s customizable, so we don’t waste any space on our service trucks,” Gonzalez concluded.

It all started two years ago. A ruggedly handsome man in an impeccably tailored tuxedo showed up on the jobsite with a valuable piece of advice: there’s a faster, cleaner and more efficient way to change your equipment’s oil and fluids — and it’s about time.

It’s Time to Clean Up Messy Oil Changes

If the Cleanest Man on the Jobsite can teach us one thing, it’s this: With the right equipment, changing oil doesn’t have to be a dirty job. Sage Oil Vac fluid exchange systems are designed to minimize oil spillage on the jobsite. After all, oil belongs in your equipment, not on your boots. Isn’t it time to experience a less messy way to do a common, yet highly important job on your jobsite?

A Faster Way to Change Oil and Fluids — It’s About Time

The Cleanest Man on the Jobsite also knows that time is of the essence on any jobsite. An idle piece of equipment is a piece of equipment that’s not making any money. With a Sage Oil Vac system, changing oil is a quick sprint instead of a marathon. It’s time to cut down your oil change time and get your equipment back to work.

Have Time to Save Time?

The Cleanest Man on the Jobsite will continue to tell the world about a faster, cleaner and more efficient way to change oil and fluids. But when it comes to your jobsite, rest assured a member of the Sage Oil Vac sales team is standing by with plenty of time to discuss how a Sage Oil Vac fluid exchange system can improve your operation. Here’s a hint: it’s about time.

The Sage Oil Vac team will be at the Work Truck Show in Indianapolis, Indiana next week. Visit us in booth #3067 in the Exhibit Hall where we will be showcasing:

- Our redesigned Lube Truck

- With a variety of tank combinations, all oil tanks utilize the Sage Oil Vac exclusive pressure and vacuum system to load fresh fluid tanks.

- Class 5, 7 and 8 options available.

- All tanks are fitted with a float and pressure gauge that is displayed on the remote panel, informing the user of vacuum/pressure levels captured in the tank, as well as the current fluid level.

- Heritage Lube Skids

- The Heritage skid design features built-in forklift-friendly transport and has plenty of capability for large fleet services.

- The patented Sage Oil Vac Vacuum process is used to load fresh fluid.

- A favorite of work trucks, the vertical tank design gives it a small footprint.

- NextLube Monitoring System

- The intuitive touchscreen controls provide real-time fluid levels and displays gallons of fresh fluids available.

- The central, easy-to-use control panel allows the operator to label tanks for better fluid organization.

The four-day show is the must-attend event for the work truck industry. The Sage team is committed to keeping up with the ever-changing needs of our customers. We work closely with manufacturers to bring you improved maintenance technology with our revolutionary mobile lube exchange systems, customization options and accessories.

For more information about the Work Truck Show or to register to attend, visit worktruckshow.com.

Evolving customer needs, a changing workforce and new technology are changing the marketplace for fuel and lube trucks.

“Our customers are working in a different world than they were just a few years ago. Between the chassis redesign, features and technology, we’re devoting a lot of resources to keeping up with what they need,” said Sage Oil Vac CEO Aaron Sage. “Construction companies spend hundreds of thousands of dollars on fuel and oil, and we want to make sure we’re helping them do their job serving their customers.”

A newly redesigned lineup of Sage Oil Vac lube trucks directly addresses operator concerns and provides the tools and technology to help operators make the most efficient use of their time. The new trucks — non-CDL models (Class 6), as well as Class 7 and 8 — not only help operators work more efficiently, but add tools that help them better meet the needs of those operating the machinery they’re servicing. The new trucks come at a time when changes in the workforce are creating challenges for machinery maintenance service providers around the country.

Industry demographics

One of the changing industry dynamics driving the evolution in lube and fuel service trucks exemplified by the new lineup of Sage non-CDL (Class 6), Class 7 and 8 trucks lies in permitting. There are fewer operators today obtaining a commercial driver’s license (CDL) than in past generations. And, the labor market for those with CDLs is so tight today, it makes it difficult for construction contractors and service technicians to find adequate qualified operators with the licenses required to operate the larger Class 7 or 8 trucks. That makes the revamped non-CDL lube truck popular, Sage said, because managers can more efficiently manage the same amount of work with a smaller, less-expensive truck.

“It’s harder to find CDL drivers, so a lot of companies — especially in the oil fields in West Texas — are looking for non-CDL applications. So, if you’re looking for a lube-only truck, these non-CDL trucks can help meet the same need without that license,” Sage said of the trucks that are built on either a Ford F-600 and Chevrolet 6500 pickup. “A lot of the big OEM dealers are using these trucks for oil, but not fuel, to conduct maintenance for rental fleet customers.”

Redesigned body

There’s an aesthetic shift in the new Sage lube trucks, but it’s not just about good looks. The new design includes panels and components to provide more solid, seamless coverage of the tools and materials the trucks are transporting. Gone are the days when a driver pulls up behind a Sage lube truck will see buckets, tools and other components that are common at jobsites. In addition to helping provide dealers the ability to better promote their businesses, the new design goes even further to promote the cleanest possible jobsite and prevent possible issues with spills that can sometimes attract punitive regulatory attention.

“You don’t see all the equipment and oil, and we do that for two reasons: First, the more you can make these trucks look nice and better shield oil and tools from view, the better,” Sage said. “And many of these OEM dealers are selling service, so they want to put a wrap or decal across the entire side of the truck with their name on it to maximize their brand’s visibility. These better-covered trucks with more seamless designs make it easier to do that.”

Managing weight

Another component of the redesign of Sage Oil Vac’s lube trucks adds efficiency by better-managing weight, a common issue for operators who sometimes face both regulatory and supply management issues with heavy lube trucks. The new Sage trucks integrate more aluminum into the chassis and components, while shifting some parts and components to different locations helps better balance overall weight across the front and rear axles.

“Weight is always a challenge, so we redesigned these trucks to optimize weight for a better center of gravity. And, we’re building more items out of aluminum for weight savings,” Sage said. “There is a lot more aluminum going into these trucks and other machinery across the industry. I think the market is more accepting of it. We are using steel where we need steel and aluminum where we need aluminum.”

Efficiency through technology

On top of the Sage pressure and vacuum delivery system that eliminates diaphragm and piston pumps — common sources for maintenance work and cost — the new lube trucks help operators work more efficiently by integrating new technology that helps better track and manage maintenance performed. Via a touchscreen monitor, the operator can track how much fluid and/or fuel is being distributed to each machine on a jobsite, eliminating a step in the process and adding efficiency. This technology that’s rapidly advancing will continue to evolve to help operators work efficiently in the field.

“Operators can assign or record gallons of fluids, then dump it onto a USB drive or CSV file to enable the customer to get live reporting,” Sage said. “You can see how much fuel and oil you’re distributing to each piece of equipment. It especially really helps larger OEM dealers work more efficiently since they don’t have to go around a jobsite and ask machine operators if they need fuel or oil. It takes that step out of the process.”

Learn more about Sage Oil Vac lube trucks and bodies. Have more questions or want to find your nearest Sage Oil Vac dealer? Contact us!

Sage Oil Vac has been servicing large fleets in Texas and New Mexico’s oil and gas energy industry that rely on generators. Generators are used for new site construction, pumping units, powering water wells, as well as for dozens of other activities. In fact, at many sites, generators run 24 hours a day, seven days a week and the expert energy operations call on when they need power is Big D Companies of Midland, Texas.

For over 40 years, the team at Big D Companies has been servicing large fleets while delivering a wide range of services, including generator rentals, open pit lining, polyethylene pipe installation, fencing and construction services. In total, Big D Construction delivers fast and reliable service to a 200 square mile territory, and operates a fleet of equipment that includes more than 100 earthmoving machines, over 330 generators and 500 miles of polyethylene pipe.

Huge maintenance needs

On any given day, Big D Companies has between 200 and 300 generators ranging in size from 20 kW to 1MW out on-rent to contractors across two states. Most of those units run around the clock, which creates short service intervals for the Big D Construction service team.

According to Trey Villanueva, operations manager for equipment rentals at Big D Companies, the company has a team of 17 people dedicated to servicing large fleets and rented equipment. “This team is responsible for providing transfer pumps to feed water trucks, supplying generators to power the water wells that feed frack pits and servicing machines out on rent,” he explained. “It’s a big job because we need to perform oil changes on most of our generator fleet every 10 to 12 days, so we try to be as diligent as possible at hitting those intervals to keep our customers up and running.”

To efficiently service the large fleet of generators in the field, Big D Equipment’s service team use Sage Oil Vac mobile lube equipment. The company owns three Sage Oil Vac 1C5G-5100 mobile lube trailers with four 60-gallon (227 liter) ASME tanks for fresh oil and fluid and one 120-gallon (454 liter) ASME tank for used oil, as well as five Sage Oil Vac lube skids that are truck mounted.

“We started with one small Sage Oil Vac lube skid and when we saw how much more efficient it was than the old way we serviced machines in the field, we added additional units until we had enough to service our whole fleet,” explained Villanueva. “We use our truck-mounted units to perform routine maintenance on generators near our offices in Midland and Pecos, Texas. Since our trailer lube systems can carry such a large volume of fresh fluid, we use those units in more remote locations and jobsites in New Mexico. Our guys can usually stay out in the field for up to three days without having to come back to the shop to refill or drain used oil — that’s a huge savings in time and travel expenses.”

Old way versus new way

Until Big D Companies invested in its first Sage Oil Vac mobile lube system around four years ago, the service team was using impeller pumps and one gallon (3.79 liter) oil containers in the field. “On average, two service techs would spend between 45 minutes to an hour changing the oil on each generator,” explained Villanueva. “They would have to pump out the used oil into buckets, replenish the oil and then transfer the used oil into sealed containers so they could be hauled back to the shop for disposal. Not only was it time-consuming and labor intensive, it was also a messy process.”

Making the switch to Sage Oil Vac mobile lube systems cut servicing time for their large fleets down to15 to 20 minutes per generator. This increase in efficiency made it possible for them to double the number of oil changes they can do each day and eliminated the need to send a second person out on routine maintenance trips. This combination has had a dramatic impact on Big D Companies maintenance expenses.

The cost-savings didn’t stop there; Villanueva explained they used to buy oil in cases because they were easier for service technicians to handle. However, now they can reap the benefits of purchasing the same Chevron oil in bulk at substantial savings. “Every day, our service technicians would have to load three to four boxes of oil onto the back of their trucks because they didn’t have a way of dispensing oil other than pouring it through a funnel,” he said. “We were paying between $16 to $18 a gallon with our old setup. With Sage Oil Vac mobile lube systems, we can quickly load our tanks from larger barrels, which is much easier and it has driven down our prices to as little as $10 a gallon. In just one year, we’ve been able to save around $12,500 on oil. The savings have been huge for us.”

The impeller pumps that Big D Companies service team used previously had a limited operational life and required routine maintenance. The company’s first Sage Oil Vac mobile lube system is still going strong and hasn’t needed much maintenance other than a few filter changes in four years. “Impeller pumps aren’t costly, but we would go through a lot of them. When they broke down on a service call, things took much longer,” added Villanueva. “Our first Sage Oil Vac mobile lube skid has been mounted on three different trucks since we purchased it. On average, we put around 250,000 miles on our trucks before replacing them. This unit has traveled more than 750,000 miles and has been almost completely trouble free, servicing a larger fleet than ever before.”

Keeping it clean

Another benefit of using a mobile lube system the team at Big D Construction and their customers appreciate is the cleanliness of the whole service process. Big D Companies has replaced its fleet factory-made drain plugs with Sage Oil Vac Femco® drain plugs, which allows the suction hose of the waste oil tank to connect directly to the oil pan of the machine without having to remove the plug. “Draining and refilling machines is easier and cleaner,” said Villanueva. “The equipment being serviced, our vehicles and our technicians all stay clean in the process. We’re able to reduce the chance of any kind of oil spilling, which helps us come across even more professional in the eyes of our customers.”

Satisfied customers best benefit of all

The team at Big D Companies knows their reputation is on the line every time a generator goes out on rent. Their customers’ operations depend on those machines to run around the clock and are acutely aware anytime they’re not. When they aren’t servicing their large fleet of equipment, they are focusing on serving their customers. Diligent preventative maintenance is the key to reducing downtime and maximizing the life of a machine, which is why Villanueva and his team’s efforts are so important to Big D Companies overall operations.

“Our president, Don Tomlin, started Big D Construction under the principle of creating economic value for our customers and ourselves by identifying new and better ways of working. Making the switch to Sage Oil Vac mobile lube systems for routine in-the-field equipment maintenance delivers value to our customers and our organization. What’s more, our initial investment was quickly recouped through cost and labor savings. It has been a win for everyone involved,” Villanueva concluded.

Learn more about Sage Oil Vac’s mobile lube systems and other ways we can help you service your fleet.

We’ve got your back! Sage Oil Vac has launched a new, three-tier warranty program (effective September 2018) to better serve customers near and far.

Why the update?

After an analysis of more than 25 years of successful Sage Oil Vac equipment lifecycles, we determined that the quality and reliability of our products continue to exceed expectations. This has encouraged us to enhance our warranty program from the previous two-year, flat warranty to a three-tier, five-year warranty program.

“This updated warranty plan further benefits customers and better positions Sage Oil Vac as a leader in the lube exchange marketplace,” said Kyle Ottmers, Sage Oil Vac Warranty Manager. “Should you invest in a Sage system, you’ll have added peace of mind with this new warranty. We’re here to support you in the off chance that something goes wrong.”

PREVIOUS TWO-YEAR, FLAT WARRANTY |

NEW THREE-TIER WARRANTY PROGRAM |

|---|---|

Items covered for the first two years:

|

Items covered for the first five years:

Items covered for the first two years:

Items covered for the first year:

|

Download our warranty policy document for a complete list of details and exclusions, then take advantage of the new policy by filling out an equipment warranty registration form for your Sage Oil Vac system.

Contact Sage Oil Vac or email Kyle Ottmers with questions about your qualifying equipment at [email protected].