The construction industry and the renewable energy markets have made a resurgence. Of course, with increased work comes the need for people to fill positions. The challenge is figuring out how to recruit field technicians. According to The Associated General Contractors of America (AGC), at of the end of September 2017, more than 184,000 construction-related jobs have been added, but there are challenges finding qualified individuals for many key positions. Those “key” positions are typically the skilled jobs that require formal training, like a field service technician.

Service technicians are in demand outside of the construction industry, too. According to the latest Bureau of Labor Statistics Fastest Growing Occupations Report, wind turbine service technician is the second fastest growing career in the country with an anticipated increase of 96 percent from 2016-2026.

While this information is great for service technicians, equipment distributors, contractors and energy companies may have some concerns: How do I hang on to quality employees? How do we recruit service technicians that are the best fit for our company? Are there ways we can do more with our current team?

Need for quality equipment

To retain and attract the best service technicians, you can either compete on wages or with quality equipment. While salary or hourly wages are important to everyone, having the best tools to perform their job day-in-day-out goes a long way for job satisfaction and improves your company’s efficiencies.

Start with the way your service technicians perform routine maintenance to equipment in the field. From oil dripping onto the ground or machine components to accidental spills when adding new oil, fluid changes can be a messy business. But it doesn’t have to be. Investing in a mobile lube system helps your service tech keep equipment components clean. Who wants to go home covered in oil every day?

Investing in a Sage Oil Vac mobile lube system will also reduce the time it takes for routine maintenance. Sage Oil Vac lube trailers, lube skids, lube trucks and lube carts use compressed air to build vacuum pressure to move fluids to and from, which is much faster than systems that use electronic pumps. With all that extra time, your service tech will be able to get more done in a day.

The team at Sage also recently introduced the NextLube monitoring system featuring a touch screen panel that simplifies oil changes. Now, the mobile service tech can monitor onboard fluid levels, pressurize tanks and automate amount of fluid dispensed. And from the shop, you’ll be able to access the same information as your mobile technician. It’s an innovation that will also help you get new service technicians up to speed quickly. Investing in quality equipment is how companies can recruit field technicians.

Recruit and retain the best field technicians

When equipment on the job isn’t running because of a breakdown or routine maintenance, your mobile service technician becomes the most important asset for your entire organization. The qualified labor shortage and increasing demand for service technicians throughout the industry means that now is the time to invest in the right equipment to attract and retain the best service technicians.

Sometimes the ideal equipment maintenance scenario doesn’t involve a centralized shop. In many cases, it’s best to do that work right on the jobsite. But it takes the right equipment. Sage Oil Vac lubes trucks and lube truck bodies help operators take care of that maintenance without pulling equipment from the job. Available in various truck weights, Sage lube truck bodies are available in a wide range of sizes and capacities. They feature Sage Oil Vac exclusive vacuum pressure systems, eliminating the need for high-maintenance diaphragm pumps to deliver oil and other fluids to equipment operators so they can get back to work quicker and more efficiently.

So, how do lube truck bodies help?

These features, on top of other common components that add operator ease and convenience, contribute to a more efficient jobsite. It minimizes the time required to perform routine maintenance and doing it on the jobsite instead of a shop or maintenance facility.

“Our lube trucks and lube bodies help jobsite managers and contractors get their maintenance work done quickly so they can get back to the job they’re out there to do,” said Sage Oil Vac CEO Aaron Sage. “Given we have a wide range of options, we think it’s important to make an informed decision so you’re striking the right balance and staying as productive as possible.”

Choose the right model

Selecting the right Sage lube truck or lube truck body starts with a look at your available workforce. Figure out what size of chassis and truck combination will best accommodate how you operate and service your customers. For smaller operators, those without commercial drivers’ licenses (CDLs) or who provide service to multiple locations at the same time, non-CDL lube trucks foot the bill. They’re smaller and can be mounted on a Dodge Ram 5500 or Ford F-550 truck. The total weight ranges from 16,001 to 19,500 pounds. Non-CDL lube trucks — like the Sage 55AB-6200 — have a tank capacity of up to 180 gallons. They are ideal for servicing equipment like dozers, excavators and rental generators.

If you service a larger fleet on a smaller number of job sites, a Class 7 or Class 8 truck or body provides the fluid capacity (up to 2,000 gallons) to perform oil and fluid changes on multiple machines in a single trip. On top of the Sage Oil Vac exclusive vacuum pressure system, these larger trucks feature high-capacity tanks, hoses, compressors and generators for delivering oil and fluids. And attributes like driver-side bulk fill stations, remote control capabilities and LED fluid sensors make operation more efficient and convenient.

Keep equipment running

All told, these features and components help maintenance providers deliver service to the jobsite. This can be done regardless of the size or number of machines being serviced. Sage Oil Vac lube truck bodies are vital to efficiently maintain equipment so jobsite operations can continue with minimal interruption.

“We consider our lube trucks and lube trucks bodies part of a larger system in which we can help contractors and equipment operators do a good job of maintaining their equipment then get back to work with minimal work interruption,” Sage said. “Our trucks and lube bodies were designed to keep machines running as efficiently as possible, and we’re going to keep finding new ways to continue to make that happen.”

FUNCTION OPTIONS

- Fuel and lube body

- Lube-only body

- Available in an open or enclosed body style

- Optional NextLube monitor

KEY FEATURES

- Stand-alone air compressor or truck-driven air compressor

- No-pump design for a lower cost of ownership

- LED light bars and lights

- In-house 3D custom design to meet customer specific needs

- Centralized control panel and LED fluid level indicators

- Sealed fluid tanks for contamination control

CUSTOMIZATION OPTIONS

- Custom builds for all available truck classes

- Additional components available (power washers, DEF delivery and electric generators)

- Additional storage options available with enclosed body designs

- 3D model available to pre-approve any design

Find a Sage Oil Vac dealer today! Don’t have a representative nearby? Contact Sage Oil Vac directly for more information and mobile lube equipment pricing.

BrandFX is the most trusted composite work body manufacturer in the United States and provides purpose-built solutions for five of the nation’s top six service fleets. When BrandFX’s President, Gary Heisterkamp received a request to outfit 20 vehicles with composite service bodies that include the ability to perform onsite oil-changes, he turned to Sage Oil Vac for a customized mobile lube system that can be configured to the exact specifications of his customer.

“A logging tradeshow is where I got my first chance to see a Sage mobile lube system in action,” Heisterkamp explained. “I was impressed with the technology and the speeds they are able to deliver fluid. So, when one of our large national customers asked for our help coming up with a mobile service solution at the NTEA Work Truck Show, I brought them by the Sage Oil Vac booth for an introduction where we learned about the customizable LubeBuilder system.”

Total customization

Working with the people at Sage Oil Vac, the BrandFX team was able to select the number and sizes of tanks most appropriate for the work its customer would be doing. Based on the needs of the customer, they installed a four-tank system with a storage container for used filters. They recommended their customers install FEMCO drain plugs, which allows hoses to be directly hooked up to the drain pan to improve speed and reduce the chance of spilling fluids.

“The LubeBuilder system is totally customizable, so we could set up within the truck body in the ideal configuration,” Heisterkamp added. “We positioned the controls so they were convenient for the operator and the tanks were in a position to maximize cargo and storage space. We also included space to install a used filter receptacle.”

The LubeBuilder system was quick and easy to install, and a Sage Oil Vac technician travel to BrandFX’s Iowa upfit facilities to help with the process.

A happy customer

BrandFX’s customer can now provide mobile lubrication services to one of the largest fleets of work trucks in the country. And, according to Heisterkamp, his customer is so happy with the results, they already placed another order.

Learn more about the Sage LubeBuilder system.

The Sage Oil Vac team hit the road in October for the 2017 International Construction and Utility Equipment Exposition (ICUEE) at the Kentucky Exposition Center in Louisville, Kentucky. The event featured 18,000+ exhibitors and thousands of event-goers.

The Sage Oil Vac booth showcased:

- Live demos of our patented vacuum technology

- 1C5G Jobsite Fuel and Lube Trailer

- 2H49-5 Heritage Lube Skid

- Live demos of the new NextLube monitor system

- Sage Oil Vac branded swag

- TapSnap Photo Booth

“We really enjoyed the product demo portion of the expo,” said Sage Oil Vac CEO, Aaron Sage. “It was great to see bystanders take it all in and ask questions about our products.”

Several Sage dealers also stopped by to visit with the team and to talk with potential customers.

“Customers were very interested in how our no-pump systems work,” Sage explained. “Seeing them have that ‘ah-ha’ moment during a demo was really great. We’re excited to follow up with some of the folks we met during the show.”

For more information about Sage’s presence at ICUEE or to provide additional feedback from the event please contact Chance Castillo at [email protected].

The Sage Oil Vac team is hitting the road for the International Construction and Utility Equipment Exposition (ICUEE) happening Oct. 3-5, 2017, at the Kentucky Exposition Center in Louisville, Kentucky. The three-day show provides comprehensive insight into the latest technologies, innovations and trends affecting the utility and construction industries.

This premier event is also known as “The Demo Expo” — every year, more than 18,000 exhibitors show off their products and technologies to thousands of event-goers.

“ICUEE is a great industry event — especially for those that like to see things operating firsthand,” said Aaron Sage, Sage Oil Vac CEO. “This will be our first time attending with a booth, so we’re excited to bring our best to the table.”

Sage plans to bring several pieces of equipment to the show including the 1C5G Jobsite Fuel and Lube Trailer and the 2H49-5 Heritage Lube Skid. Several members of the Sage team will also be on-site to answer questions.

“In addition to our extensive selection of products at the Sage booth, we are going to be showing a live demo of how our patented vacuum techonology works,” said Chance Castillo, Sage Oil Vac Dealer Development Manager.

According the the website, ICUEE covers more than 25 acres of indoor and outdoor exhibits and product demonstrations. Attendees can expect to see equipment with various functions from all-terrain carriers, attachments and components, to earthmoving and environmental, and more. The machinery on-site is also exhibited in job-like conditions so audience members can see the machinery in action.

For more information about ICUEE or to register to attend visit ICUEE.com.

Sage Oil Vac most often supplies LubeBuilder systems to customers with crane bodies, work trucks and van installations but as the popularity of the system increases a need for additional used filter receptacle (UFR) options has presented itself. To better meet the needs of our customers’ unique install situations we are now offering:

- Wall-mounted UFRs

- Top side pack mounted UFRs

- Inside side pack cabinet mounted UFRs

- Top open UFRs

- Front door opening UFRs

The wall-mounted UFR is tall with a narrower width. It works great for van or enclosed body installations where it can be anchored to a wall to help support it. It would also work well up against the inside wall of a tall work truck body. The door opens toward the operator and the hinge runs vertically. The top side pack mounted UFR design is meant for the top of a side pack on a service body. The lid opens up like a traditional UFR and the operator can access it from the ground or from the bed. The additional UFR are meant to be mounted inside the bed of the body on the floor. These come in different sizes like 14, 24 and 30-inch widths for a variety of options.

The Sage UFR has been one of our standout featured products since the inception of the company. It is valued by all industries as an essential tool to complete clean oil changes. The UFR works by allowing oil filters to hot drain, which ensures the cleanest possible solution for oil changes and filter changes in the field. Nearly every Sage Oil Vac unit has a UFR as part of the standard equipment offering and over the years UFRs have also been incorporated into Sage skid, trailers and now LubeBuilder designs.

For more information about Sage Oil Vac’s LubeBuilder system or Used Filter Receptacle products, visit SageOilVac.com or contact a dealer near you.

Not enough good things can be said about wind energy. For years scientists have urged world leaders to encourage countries to create alternate sources of clean energy, like wind power, a priority and it seems many have listened. According to the Global Wind Energy Council, the number of wind turbines spinning around the world at the end of 2016 was 341,320. Not only is this great news for our environment, it’s great news for Sage Oil Vac.

Benefits of Wind Power

- Clean energy source

- Sustainable

- Cost effective

- Establishes jobs upon set up

Wind turbines which convert the energy from wind to generate electricity, require a gear box to function and maintenance is essential to keep parts working properly. Sage Wind Turbine Generator Solutions systems were designed to provide turbine service providers with a safer way to manage oil, antifreeze changes and more. The Gear Oil Exchange (GOEX) unit which was designed in 2007, and the Flush and Rinse unit which was designed in 2010, are now in over 15 countries around the world. In 2016-2017, Sage added Mexico, Japan and Brazil to that list.

“Japan and Mexico are fairly new to the wind energy marketplace,” said Sage Oil Vac CEO Aaron Sage. “It’s great to see our products helping in such a beneficial industry. We’re looking forward to increasing shipments around the world to make turbine servicings easier and safer to manage.”

The GOEX features an onboard filtration system that cleans oil to meet ISO-approved levels with zero-cross contamination to significantly reduce the amount of wear particles in gearboxes. With cleaner oil and a greater frequency of oil changes, you can significantly increase the lifetime of any wind gearbox. A rinse and flush process is also required in turbine maintenance to remove contamination and sediment in many wind turbine gearboxes. Both units provide proactive maintenance approaches to help increase lubricant life and equipment durability.

For more information about Sage Oil Vac’s wind solution offerings, visit SageOilVac.com or contact a dealer near you.

Murphy Contracting Company, a commercial, industrial and residential earthmoving business located in London, Ontario, Canada, was established by Ron and Karen Murphy in 1999 with three scrapers and one bulldozer to their name. However, in the past 18 years, the Murphy fleet has grown to more than 150 pieces of equipment and now two Sage Oil Vac Lubebuilder systems.

“It took a lot of work to get this far,” said Dan Sullivan Mechanic at Murphy Contracting. “At the 2017 CONEXPO we purchased a Sage LubeBuilder system to install on a couple of our trucks. The kit arrived and we were able to install it in-house. The install went fairly well — it was a bit tricky getting everything we wanted in such a small area on our trucks, but with the variety of tank configurations it worked out very well.”

The Sage LubeBuilder system was added to two Murphy Contracting PM trucks with the following specs:

- 80-gal. used oil tank with a 50-ft reel

- 30-gal. fresh oil tanks with 50-ft reels

- 60-gal. fresh oil tanks with 50-ft reels

“We pride ourselves on our commercial, industrial and residential site work abilities,” Sullivan said. “These Sage Lubebuilder systems have only expedited our ability to complete construction contracts efficiently and quickly now that we can service equipment on-site. I really enjoy being able to vaccum oil — not having to pump or gravity feed oil to fill product tanks makes the process very convenient

Sullivan says the LubeBuilder systems have cut Murphy equipment service times in half.

“It is important to have the right tools for the job,” Sullivan said. “We have reached the size where we can cater to the diverse requirements of our valued clients. Since inception, one of our main goals was to expand our capabilities. From our ability to complete cell excavations, to methane gas lines, to leachate systems, to landfill cell liners — we have completed projects of various sizes and complications to reach that goal.”

For more information about Murphy Contracting and their services, visit MurphyContracting.com.

Download and share this customer story.

This March, Sage Oil Vac launched its first-ever Lube Skid Sweepstakes at the 2017 CONEXPO-CON/AGG Show. For four days, hopeful attendees entered our drawing to win the use of one of our covetted lube skids for an entire year. With hundreds of participants, the odds were favorable to many but fortunate to just one winner.

Meet the winner — Brandt Boone, Equipment Manager of Lester Contracting in Port Lavaca, Texas, entered the Sage Oil Vac booth just like countless others, but the luck of the draw put him a cut above the rest.

“I went to CONEXPO with some of my Lester Contracting counterparts,” Boone said. “I have been interested in the past year or so in getting the company a lube skid for our mechanics, so we were visiting as many people with skids as possible to see the things they had to offer.”

Lester Contracting has served the surrounding areas of South Texas as a civil contractor since 1959. Their primary services include dirt work and utilities (water and sewer).

“The Lester Contracting Vice President received an email that we had won and I was excited to try out the lube demo,” Boone recalled. “It will give us something to do our large-scale and smaller oil changes ourselves. At the moment we actually have to (hire out) to have some of our large-scale oil changes done.”

The Sage Oil Vac Lube Skid Sweepstakes offered its winner the chance to choose the lube skid that they will get to use for their demo period. With eight different models to choose from, the Lester Contracting group went through each model with a Sage representative to decide the right fit for their company.

“I set up a conference with two of our heavy machine mechanics and we talked about our large-scale oil changes and what we needed,” Boone said. “We talked about the types of oil we needed for each machine and we kind of came to a consensus of how we would want our skid to be built and what types of tanks.”

Lester Contracting decided to go with the 2H48-5 Heritage Lube skid with one 120-gallon used oil tank, four 60-gallon fresh oil tanks, five 50-foot reels and a grease package to be placed in an enclosed trailer. Each Heritage model is built to be robust and heavy duty with a smaller footprint — the perfect choice for trucks.

“Our Sage Oil Vac lube skid line is what really sets us apart from competitors within the industry, so we’re eager to hear feedback from the Lester Contracting company as the demo year progresses,” said Aaron Sage, Sage Oil Vac CEO.

Boone also anticipates the year to come with the Sage Heritage skid and is excited to bring boosted productivity and cost savings to the company.

“If we can cut costs and save money using a Sage skid that would be extremely beneficial to our company,” Boone said.

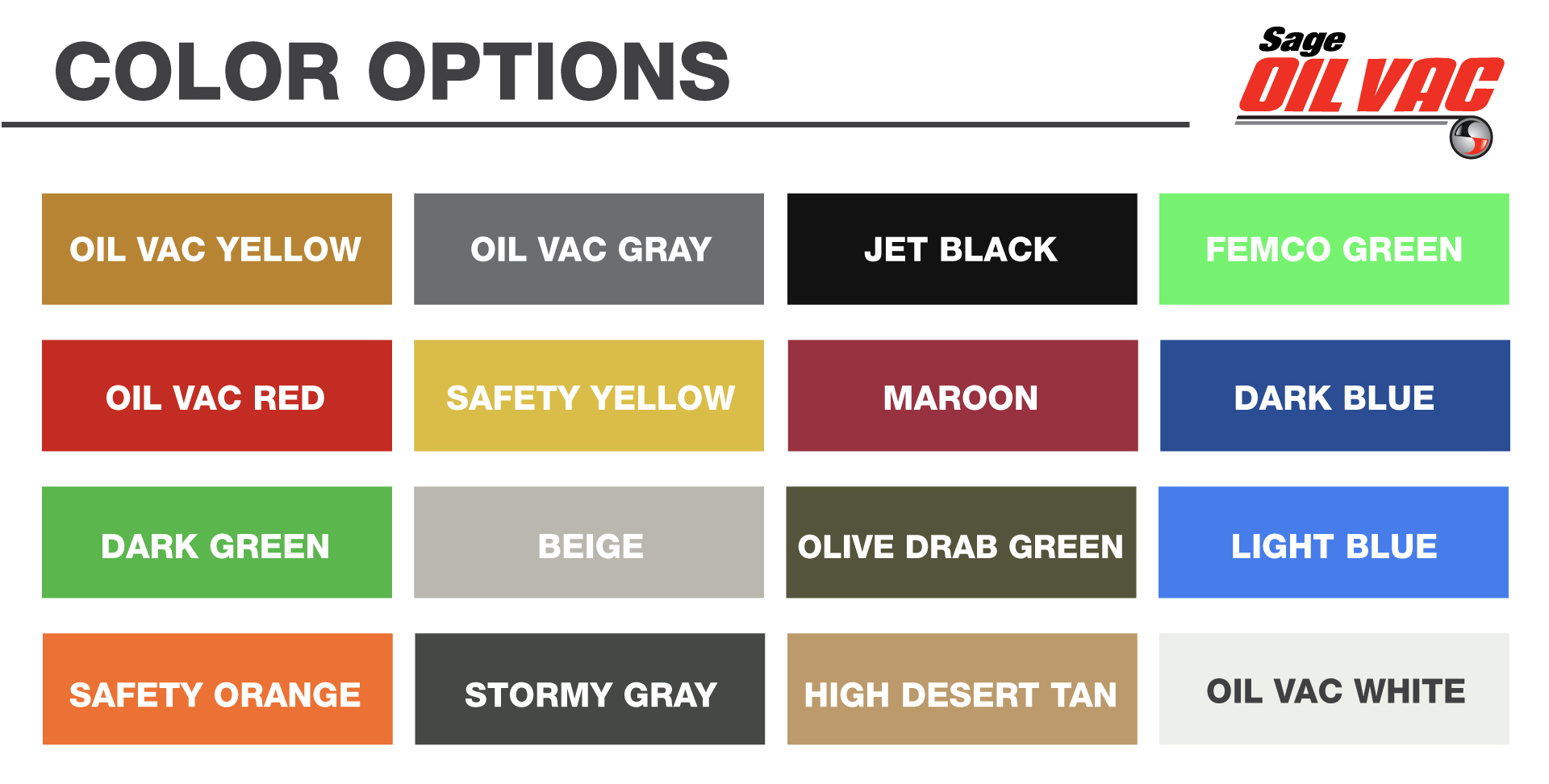

You asked and we listened. Sage Oil Vac is now prepared to bring your mobile lube equipment dreams full circle with our new custom color options. For years, the standard color for truck bodies has been oil vac white, and the standard colors for trailers, skids and carts have been oil vac yellow tanks with oil vac gray unit frames. But after seeing the increasing inquires for custom colors, Sage decided it was time to create more options. For an additional per unit upcharge, we now offer a select palette (see below) of new paint choices. Customers can also elect to provide their own color specifications outside of the color palette, but will be subject to an additional one-time color match fee.

Sage Oil Vac Paint Process

1.Verify paint selection with customer.

2.Pressure wash frames with a degreaser to remove mill oil and blast fabricated frames with Garnett, to prep to surface for paint.

3.Paint system using PPG Industrial Urethane DTM paint.

4.Touch up product as needed.

Please contact Sage Oil Vac for more specific paint information and custom pricing upcharges. View the color options here.