Is a Class 8 Service Truck Right for Your Work?

Mobile maintenance is key for heavy equipment fleets. Because once heavy equipment makes it to the site, it stays there until the job’s done. The real challenge is finding the right preventive maintenance and fueling solution to keep all those machines running at peak performance.

Heavy-duty fleets call for high-volume fuel/lube equipment, which means you’re looking at a truck. If you’re fueling and servicing a large fleet (or even just a few pieces of mining equipment), you may need something with more capacity than a non-CDL option. That leaves either a Class 7 and Class 8 model as the best fit for your operational needs. But how do you know if a Class 8 service truck is right for your work?

What industries typically use Class 8 lube trucks?

Class 8 service trucks are used to maintain all kinds of equipment, but they’re more common in industries with large heavy equipment fleets.

“Our customers looking for Class 8 trucks typically work in mining or on large-scale construction projects like building highways or large commercial properties,” said Sage Oil Vac CEO Aaron Sage. “They’re maintaining and fueling a lot of big equipment, like haul trucks or earth-moving machines.”

When does a Class 8 truck make sense?

Both Class 7 trucks (straight trucks with a gross vehicle weight of 26,001 to 33,000 pounds [11,794 kg to 14,968 kg]) and Class 8 trucks (straight trucks with a gross vehicle weight of greater than 33,000 pounds [14,968 kg]) require CDL-certified drivers. If you’re considering a Class 7 truck, it’s worth checking out a larger model, too. It’s all about balancing your fueling and maintenance needs with your equipment investment. Here are a few scenarios where Class 8 service trucks make sense.

You need to maximize efficiency while maintaining a large heavy-equipment fleet.

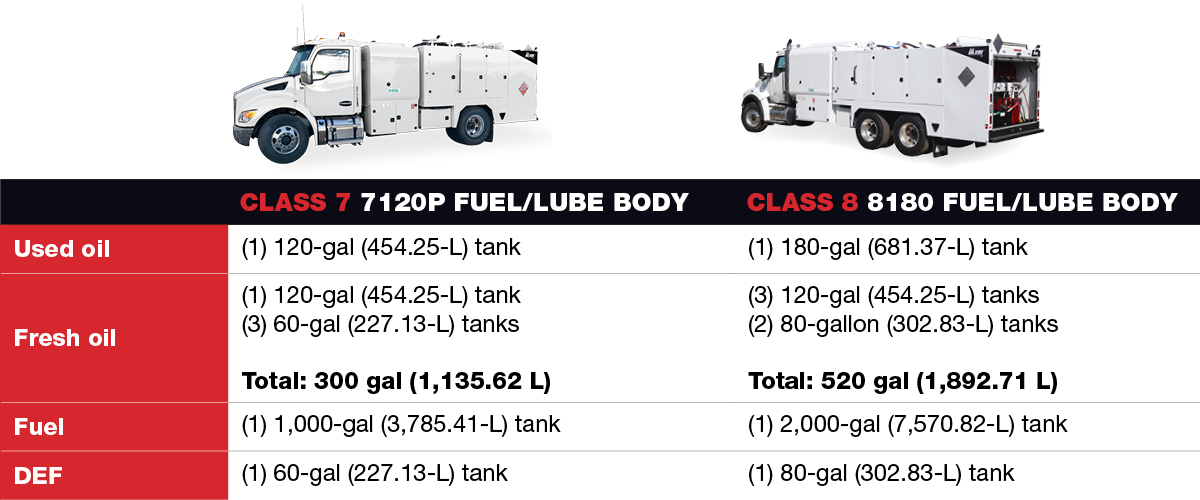

Class 8 lube trucks have a significantly higher capacity than Class 7 trucks — which means you can finish more service visits without restocking fluids. Just look at the difference between the two models in the Sage Oil Vac lineup.

When you’ve got a large fleet of heavy equipment to fuel up, 1,000 gallons (3,785.41 L) can go fast. Same with 300 gallons (1,135.62 L) of fresh oil. If you’re consistently using that volume of fluids (or more), it could be worth doubling your fuel capacity with a Class 8 service truck. A bigger truck also means more storage space for everything technicians need on the job.

You need lube equipment that can handle elevation change and reach remote sites.

As you’ve heard now, Class 8 trucks are most commonly used to service equipment on commercial construction, highway construction, mining and quarry sites. And that’s not just because they have the fuel and lube capacities to maintain large equipment. Compared to Class 7 models, Class 8 lube trucks use engines with a higher displacement volume. As a result, they have the power to handle higher payloads — even while tackling elevation changes.

What other factors should you consider?

Class 8 lube trucks are a great fit for crews with busy maintenance schedules. Even so, you’ll want to weigh your options before you commit to a maintenance solution this size.

“Not every operation needs a Class 8 service truck,” said Sage. “But if you’re working with those high capacities of fuel and lube, it’s worth weighing your options.”

Compared to smaller trucks, Class 8 models have limited maneuverability. They’re larger vehicles, which can make them difficult to move around tight jobsites or urban environments. Their size — combined with their heavier payload and higher displacement engines — also impacts their fuel economy.

Finally, a Class 8 service truck is an investment. You should carefully consider your volume of maintenance work (both now and as your business grows) before you make your decision.

Why do crews choose a Sage Oil Vac Class 8 body?

Most Class 8 lube trucks use mechanical pumps to transfer fluid into and out of equipment. The Sage Oil Vac 8180 fuel/lube body is designed with exclusive pump-free technology, using compressed air to move fluids. That translates to faster, safer, cleaner and more reliable fluid exchanges.

- Faster: Compared to traditional pump-based systems, Sage Oil Vac equipment takes less time to vacuum-fill tanks and dispense products.

- Safer: Sealed tanks protect operators from fumes and the environment from spills. That’s increasingly important as jobsite requirements become stricter.

- Cleaner: Fewer contaminants can enter the system, thanks to sealed tanks.

- More reliable: Rounded tank corners that eliminate cracking. Fewer moving parts to minimize maintenance. Bottom-draining to prevent sludge. Sage Oil Vac systems are designed for minimal maintenance issues and a lower overall cost of ownership.

A variety of tank combinations are available, allowing crews to tailor their setup to their work. The body also includes individual control panels for ease of use in the reel cabinet, continuous LED fluid level monitors and a bulk-fill station for fast fill of oil.Find the right truck with help from Sage Oil VacYou don’t have to decide on the right maintenance solution alone. The Sage Oil Vac team is here to help. Get in touch to explore all your options. Not ready to chat yet? Try our Product Match Tool to get a recommendation based on your work. All you have to do is answer a few multiple-choice questions.